Flake Flooring — Epoxy vs. Polyaspartic — What Is The Difference?

Concrete floor coatings have become a must-have for residential garages, commercial facilities, and industrial spaces — not just for protection, but for aesthetics, durability, and ease of maintenance. Two popular options for flake floors are polyaspartic flake systems and epoxy flake systems. At first glance, they look similar — but there are key differences in performance, application, and longevity that every property owner, superintendent and project manager should understand before choosing.

What Are Flake Floors?

Before we compare the systems, let’s clarify what flake floors are:

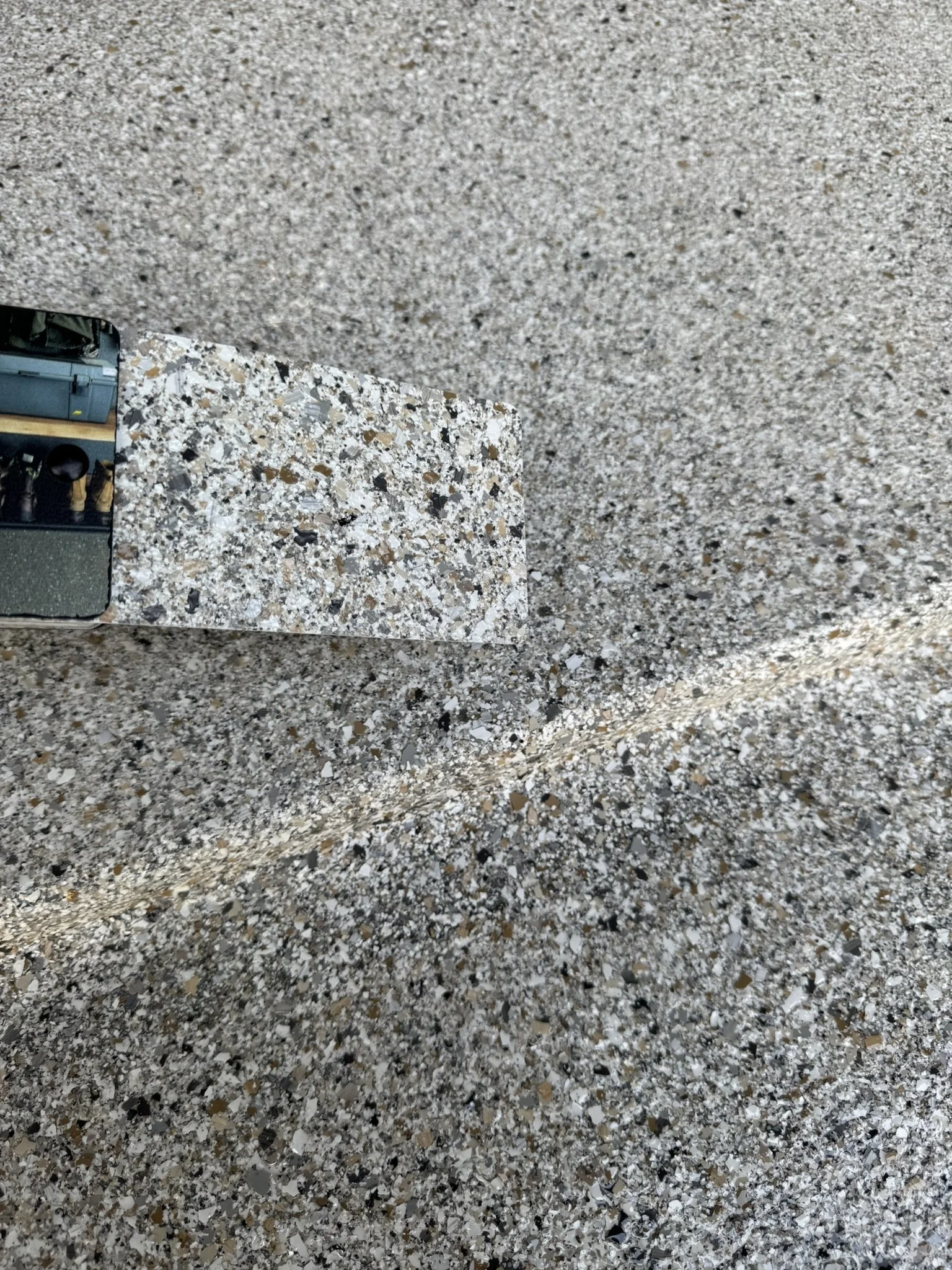

Flake flooring involves broadcasting decorative colored chips (flakes) over a base coat material to create a multidimensional, slip-resistant surface. The flakes embed themselves within the basecoat creating beautiful, impact resistant surface many are familiar with. Flakes come in a wide variety of colors and blends, allowing floors to complement any design style.

System Breakdown: Polyaspartic Flake vs. Epoxy Flake

Polyaspartic Flake Flooring

Polyaspartic coatings are part of the polyurethane family. They were originally developed for industrial applications requiring fast set times and strong chemical resistance.

Key Features:

Fast curing: Often walkable in just a few hours.

UV resistance: Excellent protection against yellowing and discoloration.

Durability: Superior abrasion and impact resistance.

Flexibility: Can expand and contract with concrete better than traditional epoxies.

How the System Works

Primer coat (polyaspartic)

Flake broadcast

Top coat (polyaspartic clear)

Epoxy Flake Flooring

Key Features:

Epoxy base coat: Superior adhesion to concrete, a longer cure time allows the epoxy to soak into the pores of the concrete

UV Resistance: Polyaspartic clear coats protects the floor for years

Enhanced impact resistance: Thicker layers of materials, and a deeper bonds creates higher impact resistnace

How the System Works

Epoxy base coat

Polyaspartic binder coat

Flake broadcast

Polyaspartic clear coat

The Truth: Concrete Is Porous – Polyaspartic Is Fast & Epoxy Is Slow

Concrete coatings need time to soak as deep as possible into the natural pores of the concrete, this is what creates a strong bond

Polyaspartic has a very fast gel (cure) time, which limits penetration into the substrate

Less penetration = more reliance on a shallow surface bond (this is where hot tire pick up happens)

Epoxy cures slowly (~12 hour cure time at 70°F), this ensures deep penetration into the surface, creating a strong surface to build upon

Flake flooring with epoxy basecoats deliver a better finish compared to a thin polyaspartic only system that will telegraph the uneven areas of the concrete

Summary:

In short: polyaspartic systems have been tailored by installers, for installers because they offer a fast-turn around time and reduce the labor cost of projects by cutting 2-3 days out of the process, but is this the best practice? We don’t think so.

The primary reason polyaspartic only systems have become more and more popular is because of the quick turnaround time, but what is the cost? The cost is gambling a sufficient bond to the concrete. Polyaspartic coatings set so fast they don’t have sufficient time to soak deep enough into the substrate, this is a bond breaker.

The best flake flooring systems blends epoxy and polyaspartic, utilizing the strengths of both materials to deliver a superior, long-lasting product to our customers.

Ready to upgrade your concrete floors? Let the experts at Tri-Co Industries, Inc. help you choose the right flooring system for your space. We proudly serve residential, commercial and industrial clients throughout North Georgia with durable high-quality concrete coatings options. Contact us today for a free on-site evaluation and estimate!